Welcome to our websites!

News

-

Congratulations! Zhelu Company’s last order before Chinese spring festival

Before the Chinese spring festival, Zhelu Company exported its last equipment order for an aluminum recycling production line. Zhelu Company’s previous market strategy in Central Asia attracted batches of powerful manufacturers from Central Asia to visit the factory and ...Read more -

Zhelu-Develop in cooperation and be responsible for every customer

Foshan Zhelu Metallurgical New Materials Co.,Ltd. is mainly engaged in aluminum industry melting and casting equipment, aluminum profile production line equipment and consumables used in all processes. We have more than ten years experience in the industry and have the a...Read more -

The global aluminium industry is in the process of transitioning towards low-carbon sustainable development

The global aluminium industry is in the process of transitioning towards low-carbon sustainable development. More than 75 percent of countries are now committed to net-zero targets, including major economies such as China, the US and the EU. A growing number of countries, cities, businesse...Read more -

Aluminum profile industry extrusion operation instructions (Last)

3.9 Stretching Precautions: 3.9.1 When the jaws are clamping the profile, do not hold your hand on the clamped part to prevent pinching fingers. 3.9.2 When the oil level is lower than the lower limit, the filter is blocked or the oil temperature is too high, stop the oil pump operation. 3.9.3 Whe...Read more -

Aluminum profile industry extrusion operation instructions (TOP)

1. Purpose: Standardize extrusion operations, improve production quality and efficiency, and prevent safety accidents. 2. The scope is applicable to the entire process of daily production operations in the Zhelu company’s extrusion workshop. 3. Operation process: 3.1 Extrusion operating pro...Read more -

Aluminum profile industry extrusion operation instructions (Medium)

3.4 Interruption operating procedures: 3.4.1 When the extruder discharges the material, clamp the material head with the tractor, turn on the cooling fan at the same time, and turn on the water cooling system for the profiles that require water cooling. 3.4.2 Use an saw to cut off about 1250px ...Read more -

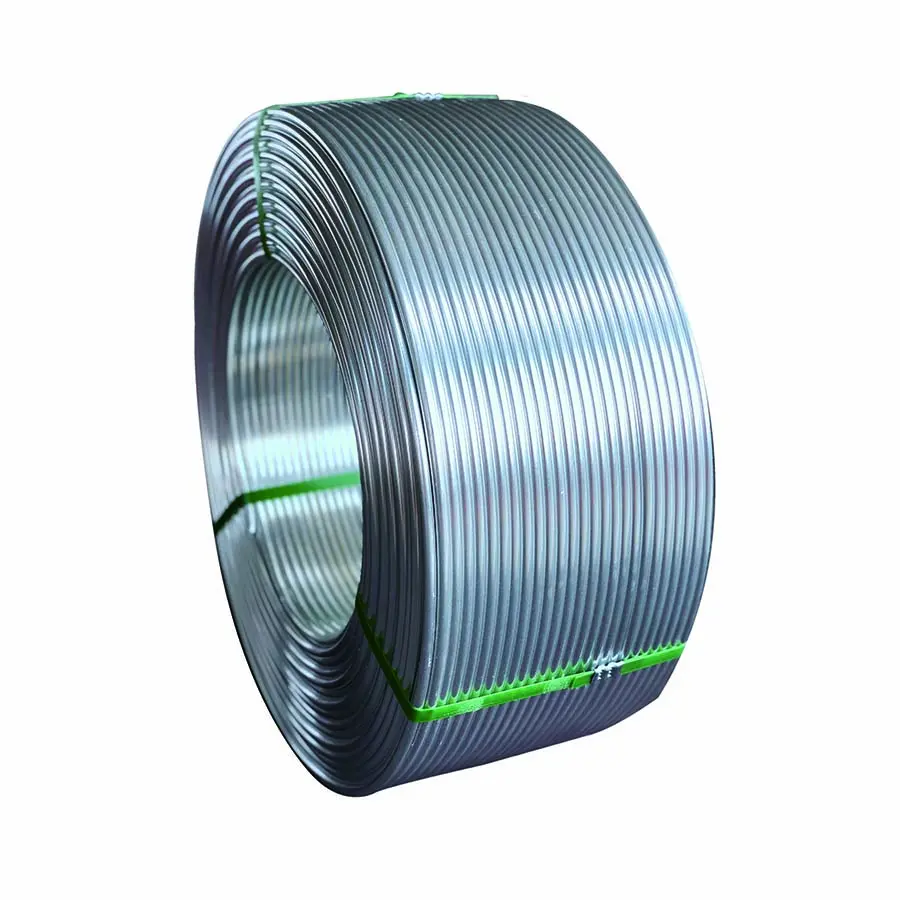

Al-Ti-B boron wire additive: the best solution for grain refinement of aluminum and aluminum alloys

Aluminum has become a widely used material in various industries due to its high strength and excellent corrosion resistance. However, aluminum’s natural properties have certain limitations, particularly in terms of surface quality. To overcome these limitations, grain refinement of alumin...Read more -

Aluminum billet melting and casting process and operation (Last)

(11)Casting: Our factory adopts equal-level close-packed hot-top casting Standard before casting 1. The talcum powder used when making molds must be smooth and firm; 2. The distribution launder, ceramic launder and pipe must be coated with a thin layer of talcum essence, and no iron should be ex...Read more -

Aluminum billet melting and casting process and operation (Top)

(1) Preparation for melting furnace (2) The furnace heated should be completed before adding materials and all furnace materials should be prepared. It must be heated when the furnace are newly built or over-hauled or stop production. (3) Ingredients and preparation 1. The selection of raw mater...Read more -

Aluminum accessories in aluminum casting process

The aluminum casting process is inseparable from various accessories. These accessories play an important role in cast aluminum alloy products. The first is the ceramic launder, which is an important tool for transporting molten aluminum from the furnace to the casting mold. It is designed...Read more -

Types and use of graphite crucibles

In the aluminum casting process, the melting equipment is important, but different factories has different demand. Some small facroty uncessary need the melting furnace or any professional machine due to the factory size, labor cost and order. At this time, they can choose the graphite crucible t...Read more -

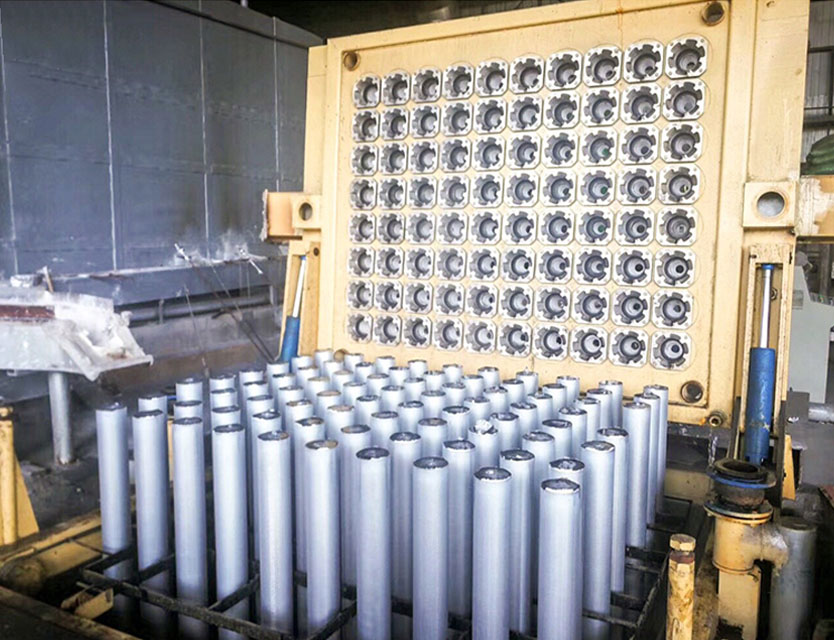

Application of crystallizer in hot top casting

The application of the crystallizer in hot top casting has brought huge changes to the aluminum billet casting process. It is an important component to ensure that aluminum liquid solidifies into aluminum rods. The crystalliser is a key component of the casting machine system and needs to be rep...Read more